Export Enquiry : 09321065457

Local Enquiry : 8928909818

Export Enquiry : 09321065457

Local Enquiry : 8928909818

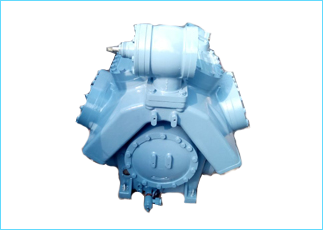

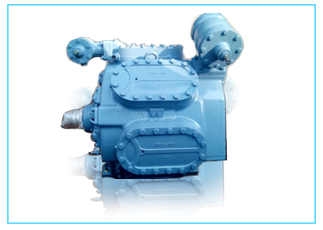

Himanshu Industries is recognized as the Manufacturer and Exporter of Industrial Air & Gas Compressor Spares Himanshu Industries is Certified as ISO -9001:2000 by ICR-ANAB. We offer a wide range of Refrigeration

A refrigeration compressor is a vital component in a refrigeration system that plays a crucial role in cooling and maintaining the desired temperature in various applications, such as refrigerators, air conditioners, freezers, and industrial refrigeration systems. Its primary function is to circulate refrigerant gas within the system, compressing it to increase its pressure and temperature. This compression process allows the refrigerant to release heat and then expand, causing it to cool down. This cooled and pressurized refrigerant is then sent through the system to absorb heat from the surrounding environment, effectively cooling the space or contents inside.

Key features and functions of a Refrigeration Compressor:

1.Compression: The compressor draws in low-pressure, low-temperature refrigerant gas from the evaporator (where cooling takes place) and compresses it to a high-pressure, high-temperature gas.There are various types of refrigeration compressors, including reciprocating compressors, rotary compressors, screw compressors, and scroll compressors, each with its own advantages and applications.

Refrigeration compressors are essential components in various industries and applications where cooling and temperature control are required. Industries and applications where refrigeration compressors are commonly used:

1.HVAC (Heating, Ventilation, and Air Conditioning): HVAC systems in residential, commercial, and industrial buildings use refrigeration compressors to cool or heat indoor spaces and maintain comfortable temperatures.We regularly exports our all brands compressor spares Carrier / Voltas Compressor Spares, York Compressor Spares, Sabroe / Akcell Compressor Spare, Grasso / Kirloskar Compressor Spares, Bock Compressor Spares, Diakin / Batliboi Compressor, Gram Compressor Spares, Mycom Compressor, Copeland Compressors, Vilter Compressors, Reconditioning Refrigeration Compressor, Refrigerant Oil, Refrigerant Oil Suniso Oil, Refrigerant York Oil, Refrigerant solest Oil to:

• Middle East : Egypt, Turkey, Iran, Saudi Arabia, Iraq, Yemen, Syria, United Arab Emirates, Israel, Jordan, Palestine, Lebanon, Oman, Kuwait, Qatar, Cyprus, Bahrain.

• African Countries : Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, France, Gabon, Ghana, Guinea, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Nigeria, Rwanda, Saint Helena, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia; Zimbabwe.

• Asian countries : Afghanistan, Bahrain, Bangladesh, Bhutan, Brunei, Burma, Cambodia, China, India, Indonesia, Japan, Kazakhstan, Kyrgyzstan, Laos, Lebanon, Malaysia, Maldives, Mongolia, Nepal, Korea, Philippines, Singapore, Sri Lanka.

• South American Countries : Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela.